Nanotechnology

Nanotechnology is a branch of science or technology which deals with structures at nanoscale. The size of these structures variate from 1 nanometer to 100 nanometers. A nanometer is 1 billionth of a meter or 10-9 meters. It involves the study and application of fields of science such as physics, chemistry, biology, material science and also Engineering. It is the most advanced technology in the world today. Nanotechnology is used in almost every field in the world today. They are replacing bulk materials and chemicals in all forms. They can be produced by manipulating atoms to have the desired properties and hence are good in usage compared to bulk materials.

HISTORY

The first concept of nanotechnology was given by a renowned physicist Richard Feynman in his talk "There's plenty of room at the bottom" in the year 1959 in which he described the possibility of manipulation of atoms as a more powerful form of synthetic chemistry compared to that which is used today. The term "Nanotechnology" was given by Norio Taniguchi in 1974 though it was not popular at that time. Inspired by Feyman's concepts, K.Eric Drexler wrote a book "Engines of creation: The coming Era of Nanotechnology" in the year 1986 which gained much popularity and the term Nanotechnology was popularized.

A scanning force microscope (STM) was invented by Gerd Binnig and Heinrich Rohrer in the year 1981 for which they received the Nobel prize in physics in the year 1986. The STM is capable of scanning the surfaces at the Atomic level and manipulate individual atoms. The instrument was first tested and was successful at manipulating individual atoms in the year 1989.

Gerd Binnig also invented the Atomic Force Microscope and the first experimental implementation was done by Binnig, Quate and Gerber in 1986. The AFM is also a scanning microscope and can also measure the forces at the atomic level.

HISTORY

|

| RICHARD FEYNMAN |

INVENTIONS AND DISCOVERIES

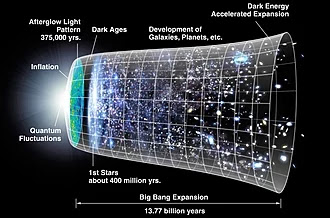

In the 1980s the Nanotechnology took a major growth through the inventions of STM (Scanning Tunneling Microscope) and AFM (Atomic Force Microscope) and the discovery of Buckminster Fullerene.

|

| BUCKY BALL C60 |

Buckminster Fullerene is a member of carbon structures consisting of 60 Carbon atoms and is shaped like a ball, it is also called as a bucky ball.The members of Fullerene Family are a major subject falling under the Nanotechnology research. It was discovered by harry kroto, Richard Smalley and Robert Curl in the year 1985 for which they got a Nobel prize in the year 1996.

NANOMATERIALS

Nanotechnology is a field that uses microscopic techniques for producing materials. These materials are called Nanomaterials. Nanomaterials are used in many industries including electronics and mechanical designs to produce various products. Nanomaterials are divided into 2 major groups called Nano-objects and Nanostructured materials.

Nano-objects are categorized on the basis of their dimensions in the nanoscale. Nanoparticles are nano-objects with all the 3 dimensions in the nanoscale ex: Nanoparticles of chemicals like silicon, zinc, potassium etc. Nanofibres have 2 dimensions in the nanoscale ex: Different polymers and fibers. Nanoplates have 1 dimension in the nanoscale and they only exist if the other 2 dimensions are significantly larger ex: Nanoribbons, films etc.

Nanostructured objects are categorized on the basis of their phase of matter. Solids with atleast one dimension in the nanoscale are called Nanocomposites. Solids which have nano pores filed with liquid with at least on dimension in the nanoscale are called Nanoporous materials. Liquid or Solids with gaseous phase where either of the phases have nano dimensions are called Nanofoams.

METHODS OF PRODUCTION

There are 2 major methods of producing Nanomaterials, they are Top-Down

method and Bottom-Up method.

Top-Down method (Ball milling technique)

Ball milling is a method of producing Nanomaterials from the top-down approach i.e from bulk materials to Nanomaterials, it is also called as mechanical crushing. It consists of 2 small balls rolling freely inside a drum. The material whose Nanoparticles are need to be produced is kept inside the drum. The balls roll over and fall on the material with the gravitational force and crushes the material. This process is carried out until the solid material is crushed into small Nano-Crystalline particles. Ball milling is used to prepare powders of elemental and metal oxides ex: Iron with grain sizes 10nm to 30nm can be formed, it is a preferred method for preparing Nanoparticles of metal oxides using the Top-Down approach.

Bottom-up method

This method involves producing of Nanoparticles from synthesizing the material from Atomic or molecular state via chemical reactions. There are different methods involved in this like Chemical Vapor Deposition (CVD), Sol-Gel process, Aerosol based processing, Sputtering or Laser Evaporation, Atomic or Molecular Condensation etc.... In all these methods chemicals are treated in different ways and Nanoparticles are formed.This method is used to form Nanoparticles of oxides and carbides, Nanoparticles of metal atoms,metal alkoxides and chlorides etc.. are formed by Bottom-Up approach.

PROPERTIES

The main reason behind the popularity of Nanoparticles over the bulk materials are their properties. Their properties differ from the bulk materials as their surface area is much larger than its volume and therefore the atoms at the surface experience a greater potential than the inner atoms and dominate the properties. In a bulk material the atoms on the surface are less than in the bulk and hence their physical properties differ.

When the material is sufficiently smaller in size i.e 10nm or less, the energy levels in which the electrons jump and fall changes, this effect is called Quantum Confinement. Due to this effect the optical, electrical and magnetic properties differ from that of the bulk materials. In bulk materials electrons have sufficient space and hence they climb and fall as per the potentials they experience and thus they both possess different properties.

Top-Down method (Ball milling technique)

Ball milling is a method of producing Nanomaterials from the top-down approach i.e from bulk materials to Nanomaterials, it is also called as mechanical crushing. It consists of 2 small balls rolling freely inside a drum. The material whose Nanoparticles are need to be produced is kept inside the drum. The balls roll over and fall on the material with the gravitational force and crushes the material. This process is carried out until the solid material is crushed into small Nano-Crystalline particles. Ball milling is used to prepare powders of elemental and metal oxides ex: Iron with grain sizes 10nm to 30nm can be formed, it is a preferred method for preparing Nanoparticles of metal oxides using the Top-Down approach.

Bottom-up method

This method involves producing of Nanoparticles from synthesizing the material from Atomic or molecular state via chemical reactions. There are different methods involved in this like Chemical Vapor Deposition (CVD), Sol-Gel process, Aerosol based processing, Sputtering or Laser Evaporation, Atomic or Molecular Condensation etc.... In all these methods chemicals are treated in different ways and Nanoparticles are formed.This method is used to form Nanoparticles of oxides and carbides, Nanoparticles of metal atoms,metal alkoxides and chlorides etc.. are formed by Bottom-Up approach.

PROPERTIES

The main reason behind the popularity of Nanoparticles over the bulk materials are their properties. Their properties differ from the bulk materials as their surface area is much larger than its volume and therefore the atoms at the surface experience a greater potential than the inner atoms and dominate the properties. In a bulk material the atoms on the surface are less than in the bulk and hence their physical properties differ.

When the material is sufficiently smaller in size i.e 10nm or less, the energy levels in which the electrons jump and fall changes, this effect is called Quantum Confinement. Due to this effect the optical, electrical and magnetic properties differ from that of the bulk materials. In bulk materials electrons have sufficient space and hence they climb and fall as per the potentials they experience and thus they both possess different properties.

APPLICATIONS

In the modern world Nanomaterials have a vast range of use in every field including Engineering, Medicine, Agriculture and Scientific Fields. They have contributed various no. of products. One of the most popular is Carbon Nanotubes (CNTs). CNTs are of the strongest products manufactured by Nanotechnology. Tensile Strength of Carbon steel is around 1.2 GPa and Diamonds which were known as the strongest materials have a tensile strength of 60 GPa. CNTs have a tensile strength of 63 GPa which is well below than the calculated strength which is 300 GPa. Since they provide much strength at a lower price, they are replacing many of the costly metals.

Nanomaterials are used in medicine in many ways. They are used as drugs and are directly injected to the cells due to their small size. They are used in medical instruments, diagnosis and in treatment of many diseases. The use of Nanotechnology in medicine is called as Nanomedicine.

They are replacing electrical components as they have different properties. Semiconductors, wires, sensors, tubes are replaced by Nano-semiconductors, Nanowires, Nanotubes, Nanosensors etc.. The use of Nanotechnology in electronics is called as Nanoelectronics.

Nanomaterials are used widely in Mechanical Engineering as they provide good strength and required properties at a low cost. Fibers and metals are replaced by CNTs and Nanofibers.

Nanomaterials are also used in agricultural field. They are used as fertilizers, food processors and many chemicals. The fertilizers made from nanomaterials are called as Nanofertilizers.

Nanomaterials are used as Enzymes or catalysts in chemical industries for a higher yield of products and greater rates of chemical reactions. They are called as Nanozymes and Nanocatalysts.

At last I just want to say is there's much more to come. The field and uses of Nanotechnology is expanding and slowly replacing day to day products. Nanomaterials are much more convenient than the bulk products. Governments are investing billions of dollars in the Nanotechnology Research.

Comment your Views and Suggestions:)

Nanomaterials are used in medicine in many ways. They are used as drugs and are directly injected to the cells due to their small size. They are used in medical instruments, diagnosis and in treatment of many diseases. The use of Nanotechnology in medicine is called as Nanomedicine.

They are replacing electrical components as they have different properties. Semiconductors, wires, sensors, tubes are replaced by Nano-semiconductors, Nanowires, Nanotubes, Nanosensors etc.. The use of Nanotechnology in electronics is called as Nanoelectronics.

Nanomaterials are used widely in Mechanical Engineering as they provide good strength and required properties at a low cost. Fibers and metals are replaced by CNTs and Nanofibers.

Nanomaterials are also used in agricultural field. They are used as fertilizers, food processors and many chemicals. The fertilizers made from nanomaterials are called as Nanofertilizers.

Nanomaterials are used as Enzymes or catalysts in chemical industries for a higher yield of products and greater rates of chemical reactions. They are called as Nanozymes and Nanocatalysts.

At last I just want to say is there's much more to come. The field and uses of Nanotechnology is expanding and slowly replacing day to day products. Nanomaterials are much more convenient than the bulk products. Governments are investing billions of dollars in the Nanotechnology Research.

Comment your Views and Suggestions:)

Explain in detail about modern and future uses of Nanotechnology such in smart phones, Smart devices.

ReplyDeletePresently there are no uses of nanotechnology in smart phones and smart devices and any predictions might go wrong. I'll surely update it when any genuine application of nanotechnology arrives.

Delete